Blog topic

Couplings for any field of application

The VMA range extends from small high-precision spring bar couplings with a maximum speed of <50,000 rpm and plug-in solutions for complex assembly situations right through to robust powerhouses for extreme loads.

Not only can each VMA coupling be adapted to suit the customer's transmission requirements, but also to cater for the specific demands of the application (such as resistance to heat or acids). This is achieved through careful selection of the right high-quality materials.

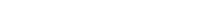

The ASK product group (pictured) comprising sliced couplings is characterized by the symmetrical arrangement of the milled slots typical of those found on spring bars. As a result, they help protect the drive and bearings in the case of axial, angular, and radial offsets. At the same time, the coupling itself remains torsionally stiff even with high-speed reversing duty. Thanks to the one-part design, a true running accuracy of 0.01 to 0.03 mm can be ensured. The standard range caters for shaft diameters of 3 – 60 mm. In addition, custom products can be supplied with non-standard diameters and lengths.

The KSK Oldham couplings have been specially developed for high-precision requirements in conjunction with demanding installation situations. Thanks to their self-fixating polyacetal link, they ensure completely backlash-free transmission in the case of reversing duty - even though they are simply plugged in.

All couplings can be combined with an extremely wide range of connections. For example, half shells, spread hubs, hollow shafts, thread shafts, or VMA’s very own clamping device can all be used to ensure a firm connection to your application. (ud)